For a long time, the full hydraulic injection molding machine has always dominated the injection molding machine market. However, with the advent and strong development of the full electric injection molding machine, the dominant position of the full hydraulic injection molding machine in the market is gradually shaken. Find answers in several ways: What are the differences between these two injection molding machines? What are their advantages and disadvantages?

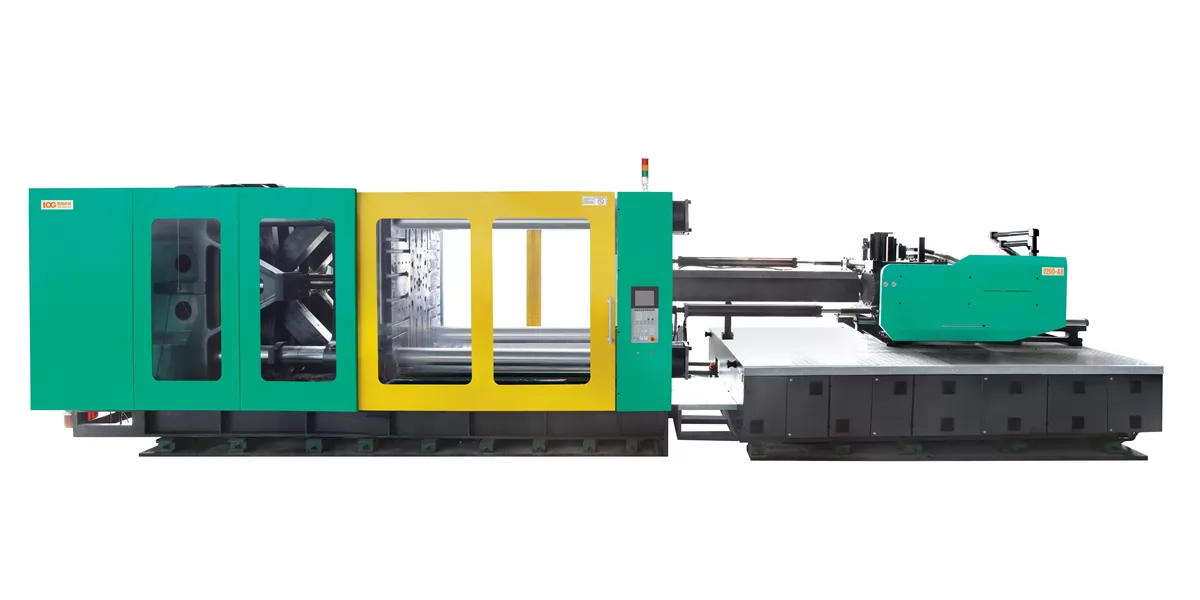

Hydraulic injection molding machine is a large injection molding machine. The action of the hydraulic injection molding machine is to control every action of the injection molding machine by controlling the flow, pressure and direction of the hydraulic power source.

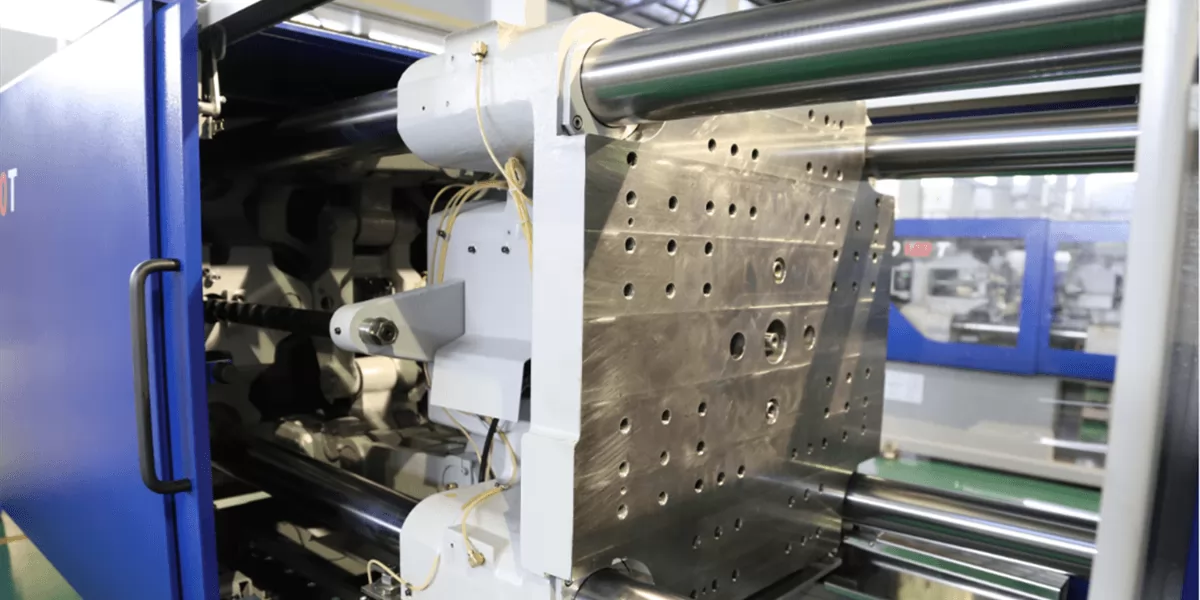

The full hydraulic injection molding machine uses hydraulic valves to control the flow direction or flow of the high-pressure hydraulic oil pumped from the hydraulic pump to drive the piston rod of the hydraulic cylinder or the hydraulic motor to complete linear reciprocating or rotary motion, but if you want to achieve the synchronized action of each axis of the full hydraulic machine, An additional hydraulic accumulator must also be configured.

The hydraulic injection molding machine can use the accumulator to achieve high-speed injection, and can also achieve special injection molding such as micro foaming. The maximum clamping force of the hydraulic injection molding machine can reach 80,000kn, which can process larger injection molded parts.

The full hydraulic injection molding machine uses valves and oil motors to complete and control the injection movement. There are many types of actuators available, and its clamping mechanism can adopt a variety of clamping forms, which makes it more able to meet the processing requirements of a variety of plastic products.

For more information, you can learn about this article: What Is a Hydraulic Injection mMlding Machine

Advantages of all-electric injection molding machine

Stable injection

The all-electric injection molding machine is less affected by external factors, its mold molding parameters are controlled by a computer, and the injection performance is stable; while the dynamic technical parameters of the all-hydraulic injection molding machine are susceptible to fluctuations due to changes in hydraulic oil temperature.

Energy saving and cost reduction

Each movement of the all-electric injection molding machine is controlled by its corresponding motor without driving other control motors, and each actuator is directly driven by electricity, its production efficiency and energy utilization rate are high, and the energy saving effect is significant. In addition, the all-electric injection molding machine does not need to use hydraulic oil, thus eliminating the need to cool the working oil, reducing the use of cooling water, and reducing production costs.

Efficient control

The application of the servo motor of the all-electric injection molding machine improves the responsiveness of the system, so its response is sensitive, the action speed is fast, and the action accuracy is high. Each part of the action is controlled by an independent motor, so the injection molding machine can perform compound actions, and multiple processes can be performed at the same time, which greatly improves production efficiency.

High precision

With the advantages of high speed, high efficiency and high precision, the all-electric injection molding machine is more suitable for processing high value-added products such as electronics, electrical appliances, high-cleanliness medical products, etc., especially for the injection molding of small parts. Its advantages of high performance and high precision injection molding.

Environmental optimization

The all-electric injection molding machine has low noise during operation, and no working oil is used in the operation of the machine, so there will be no mechanical oil leakage and other problems to keep the environment clean.

The hydraulic injection molding machine has been developed for a longer period of time, the injection volume is much larger than that of the all-electric injection molding machine, and the process is stable, and after a long time of technological development, the price is not high. Ideal for the production of high-volume parts, highly complex parts (automotive industry), high-tech product components with perfect surfaces, or thick-walled parts

Very low upfront cost

The price of hydraulic injection molding machine is low, and the price of all-electric injection molding machine of the same model is about several times that of hydraulic injection molding machine, so the cost return of hydraulic injection molding machine is faster. Moreover, hydraulic injection molding machines are relatively popular, and there are many products for sale in the second-hand market.

Low maintenance cost

Hydraulic components have higher wear resistance, low spare parts cost and high availability, thereby reducing maintenance costs. Maintenance is relatively simple and can be maintained by many service personnel, while all-electric injection molding machines usually require the assistance of manufacturers or suppliers, and cost more.

The rise of all-electric injection molding machines provides companies looking for injection molding machines with more and more excellent options. The rapid response, precision, and intelligence trend makes all-electric injection molding machines more advantageous in the future development. The only drawback is its mold clamping. The force is not strong enough. It is still necessary to use a fully hydraulic injection molding machine in the production of some large injection molded parts. At present, all-electric and hybrid injection molding machines will be an important direction for the development of injection molding machines in the future, but fully hydraulic injection molding The machine is still indispensable.

If you are looking for a suitable manufacturer to buy a hydraulic injection molding machine, you can pay attention to our products. Ningbo LOG Machinery Co., Ltd. is located in Yuyao, the kingdom of plastic products in China. It is an enterprise specializing in the production of high-tech injection molding machines. With its strong independent research and development capabilities and strict quality supervision system, LOG injection molding machines supply various types of hydraulic and all-electric injection molding machines to the market, which have the advantages of high efficiency, energy saving, high pressure and high speed, precision and stability.

You can contact us immediately for more help and product consultation.