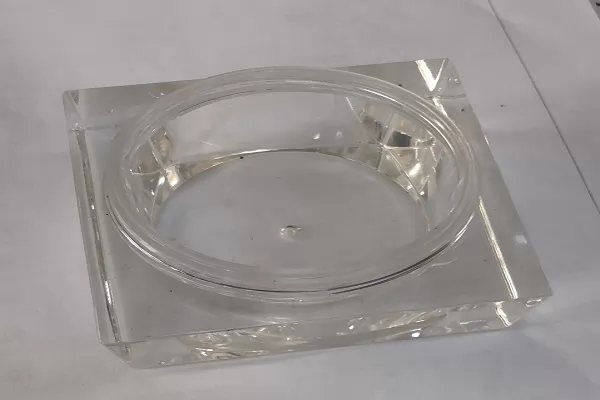

Causes and solutions for bubbles and voids in transparent plastic injection molding

(1) The melt temperature is too high. The molding temperature should be appropriately lowered.

(2) The injection pressure is too low. Should be properly improved.

(3) The boost time is too short. Should be extended appropriately.

(4) The holding time is too short. Should be extended appropriately.

(5) The mold temperature is too low. Should be properly improved.

(6) The raw material is poorly dried. Pre-drying should be carried out and the drying temperature should be increased and the drying time should be extended.

(7) There are obstructions in the flow channel. It should be completely removed.

(8) The cooling time of the product in the mold is too long. Should be properly shortened, it is best to put the demoulded product in hot water Slowly in the bath.