For all companies that use injection molding machines for production, the normal use of injection molding machines is very important, because it affects whether your production can be carried out normally, and the maintenance costs of injection molding machines are also very important expenses. Therefore, the maintenance of the injection molding machine is very important. In China, injection molding machines are very important production tools for many companies. Therefore, both Chinese manufacturers and companies that use injection molding machines attach great importance to after-sales technical support and maintenance of injection molding machines.

Next, we will take you to understand the main points of injection molding machine maintenance.

The role of injection molding machine

Injection molding machine, also called injection or molding machine, is a molding equipment that uses plastic molding dies to make thermoplastic or thermosetting plastics into various shapes of plastic products. The injection molding machine has the ability to mold plastic products with complex appearance, precise size or dense texture with metal inserts at one time. It is widely used in national defense, electromechanical, automobile, transportation, building materials, packaging, agriculture, culture, education and health. All areas of people’s daily lives. China has a large number of injection molding machine manufacturers, and they are paying more and more attention to product quality, and they are also paying more and more attention to the post-maintenance work and services of injection molding machines.

Importance of injection molding machine maintenance

In China, injection molding machines play a major role in many factories. The quality of management and maintenance is directly related to whether the equipment can maintain good working accuracy and performance for a long time, related to the failure rate and operation rate of hydraulic equipment, and The quality of the processed products is related to the improvement of the factory’s production efficiency and economic benefits; we should focus on the link of "prevention" rather than "treatment", so as to reduce equipment failures, reduce downtime for maintenance, and greatly improve the machine The economic benefits of the equipment's service life, working performance and safety performance are very obvious.

Precautions for injection molding machine maintenance

Since the injection molding machine is a very important equipment, even if it is a Chinese injection molding machine with high cost performance, the price and maintenance fee are not a small amount. Therefore, there are several very important precautions for the maintenance of the injection molding machine.

- The maintenance, repair and maintenance of the machine must be performed by experts with sufficient qualifications and rich experience in the field of injection molding machines. They should be familiar with industrial life and safety standards, and should be familiar with the structure and function of the necessary machine safety equipment.

- All maintenance work must be carried out when the main power switch of the injection molding machine is set to "0". If necessary, lock it with a padlock.

- Employers are responsible for letting operators know about the structure and function of safety facilities, and take personal health and safety seriously.

- Any work that would damage the safety facilities of the machine should be stopped.

- The employer must ensure that the operators are experienced and qualified operators.

- In any case, the safety protection facilities should not be detached from the machine or not functioning. If it is necessary to remove the safety device in order to repair the machine, you must ensure safety. After the repair work is completed, install the safety facilities as they are and check the effect.

- Any changes to the safety facilities without permission are not allowed!

Maintenance points of injection molding machine

In addition to the inspections before and after daily work, the servo injection molding machine should be regularly inspected. This is very important for the normal use of the injection molding machine and the smooth progress of the work, and it can save a lot of maintenance costs.

Monthly inspection

- Check the quality of the hydraulic oil and find that the oil contains impurities. If the oil is insufficient or contains water, it must be dealt with in time. Replenish insufficient hydraulic oil.

- Check whether the circuit of each point is loose.

- Check the ventilation filter on the electric control box, remove the dirt, and remove it for cleaning if necessary.

- Clean the hydraulic oil filter.

- Perform a cleaning treatment on each movable surface (such as the pull rod, the sliding guide surface of the injection seat, etc.), and then recoat with new lubricating oil.

Annual inspection

- Check the quality of the hydraulic oil. Generally, the hydraulic oil used in the injection molding machine is required to be replaced with a new oil every 1-1.5 years: when the new equipment is used, the hydraulic oil should be discharged from the hydraulic system of the injection molding machine after 3 months of use, and control the various controls in the hydraulic system. Valves, pipelines, and oil tanks are cleaned once (because the worn iron powder and unclean debris in the pipelines are mixed into the oil in the initial stage of the new equipment), the hydraulic oil is filtered (using a 150 mesh filter), and the Join the mailbox.

- Correct the temperature difference error between the thermocouple temperature measuring instrument display and the actual temperature measurement point measured by the thermometer; remove the dirt on the hot couple contact point, and correct the correct working temperature measurement position of the thermocouple.

- Check the firmness of all wire connection points in the control box, check whether the rubber insulation layer of the circuit is aging, prevent leakage, and replace the circuit wire if necessary.

- Check the mechanical transmission deceleration system, such as the cleaning of the bearing, check the wear condition, and replace the bearing if necessary. Check the wear condition of the gear tooth surface and the quality of the lubricating oil in the reduction box. Make a record.

- Check the wear of the screw and barrel, refurbish minor wear and scratches, and make repairs when the wear is serious, make a record, and propose a replacement plan.

- All drive motors, hydraulic pumps, and motors should be disassembled and inspected to check the wear conditions of bearings and pump bodies. After cleaning, add lubricating oil (grease), keep a record of the worn parts, and propose a repair or replacement plan.

- For some sealing rings. The wearing parts are inspected and replaced if necessary.

Buy a high-quality injection molding machine

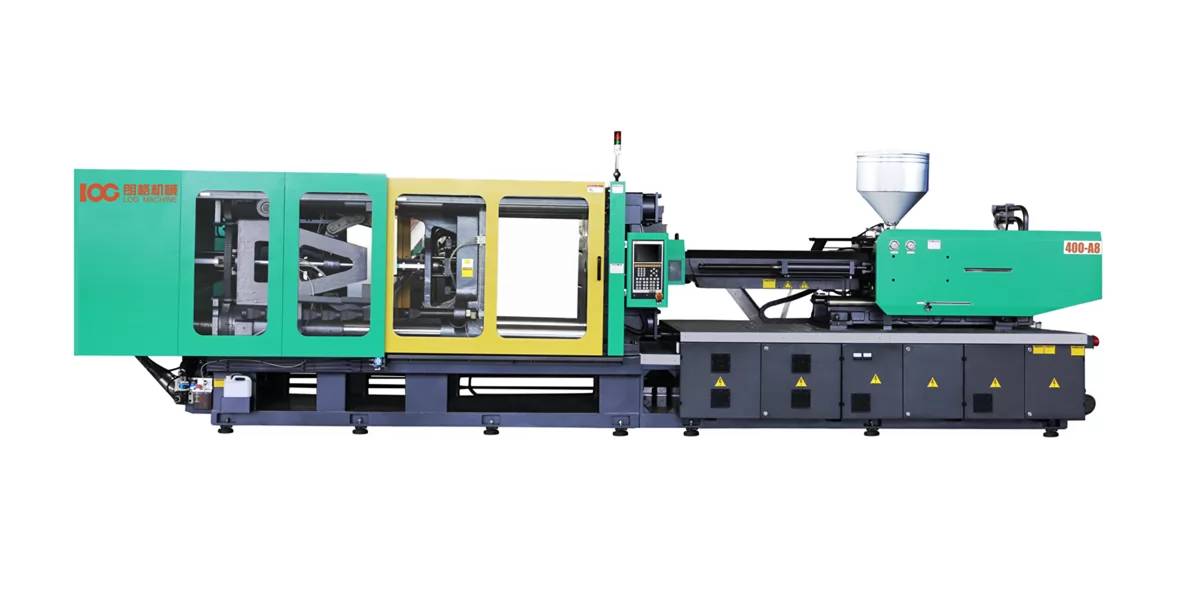

Under normal circumstances, the purchase and use of high-quality injection molding machines will also have a positive impact on subsequent maintenance and overhaul. With the development of China's plastics industry, urban plastic manufacturing and plastic molding industries headed by Ningbo are developing rapidly. Many excellent injection molding machine manufacturers have been born, and Log Machine is a very good representative of them. The products of excellent injection molding machine manufacturers not only provide cost-effective products, but also provide high-level after-sales service and technical support. Provide assistance in later maintenance and overhaul. Log can provide customers with comprehensive technical support services, so that your production has no worries.

If you want to know more information or are interested in our products, you can visit our website and contact us. We look forward to your visit.