AD 140 Ton

Request a Quote

Description

AD 140T Technical Parameters

|

Clamping

force

|

Tie-Bar

Distance

|

Opening

stroke

|

Mold

thickness

|

Screw

diameter

|

Shot

weight(GPPS)

|

Injection

speed

|

|

1370(140)kN(tf) |

540*460(mm) |

375mm |

180~450mm |

32-40mm |

108-193g |

400mm/s |

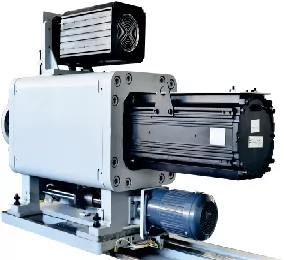

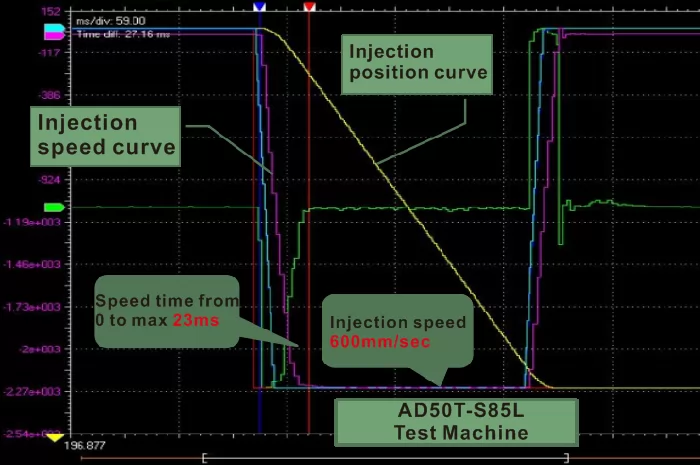

Direct Drive Mechanism For Injection

Highly responsive and high speed injection control is achieved with direct-drive structure mechanism as the core of the injection

High response ,low inertia servo motor with corresponding low inertia load design to achieve the aim of the actual closed cycle and high acceleration.

Applied rotation mechanism for the injection unit,which is more convenient for disassembling screw components and effectively reduce the operation time.

Equipped with high-precision encoder and injection pressure sensor,which could control screw position with accuracy and stabilize rubber melting,injection .pressure holding and back pressure operation.

Content-rich standard configuration

|

|

|

|

Heat cover

Adopt double-deck heat cover of

stainless steel.Reduce energy

consumption of heating system.

Avoid operator be scalded due

to mishandling.

|

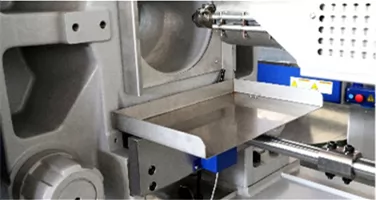

Injection safety protector

Reasonable design which avoids operator

being scalded due to mishandling and

facilitates operation,greatly improves work

efficiency.

|

Material clean-up plate

Configured stainless steel cleaning

plate under the nozzle to facilitate

waste removal,avoiding waste being left

on the gap of machine while clean-up operation

Less troubled during maintenance.

|

|

|

|

|

Chute type erecting bed for hopper

Humanized design .easily installed;

Adopts high-quality steel.stronger

and make it more durable ,safely

and reliably to use.

|

Color touch display

15 inch HD color touch display ,

its clear image makes it handy to operate,

rotatable design which is more convenient

for technical operation.

|

Three-color alarm light

When emergency occurs,the device will

remind you what kind of situation by

different colors ,you can cope with urgent

situations more easily,greatly increase the

production management efficiency.

|

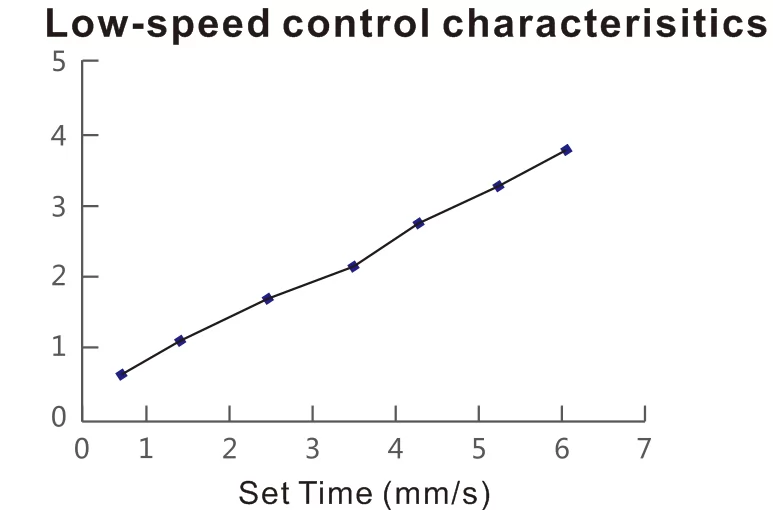

Injection speed controlled

Applied low inertia load design which could strengthen basic characteristics of injection speed responsiveness and low speed injection traceability.

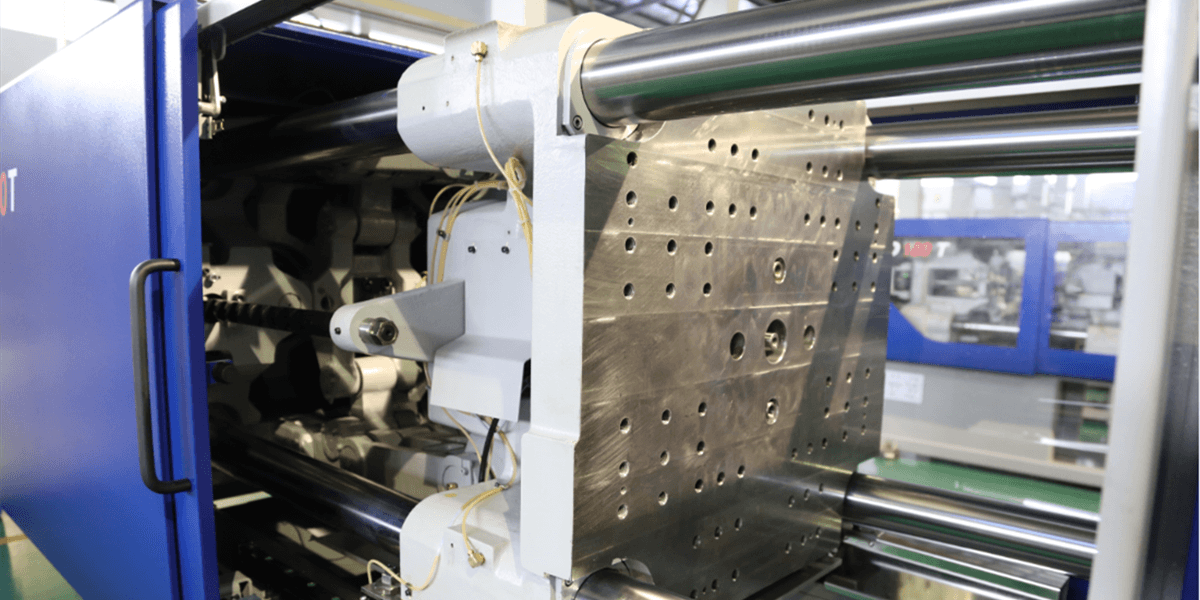

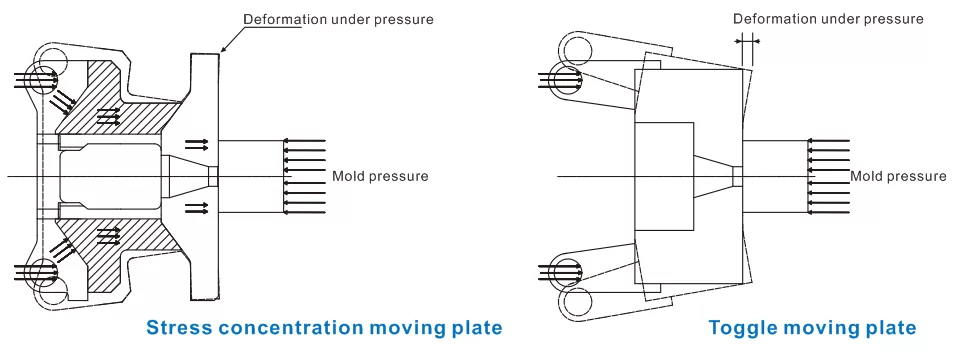

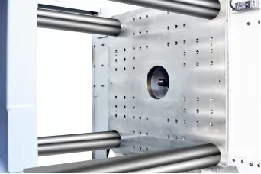

Optimized plate design

Stress concentration plate design unifies clamping force of the mold bears.improving the issues of inadequate venting and nonuniform of pressure on mold surface.what occurs on traditional toggle machines,significantly increasing the mold service life.

|

|

|

|

|

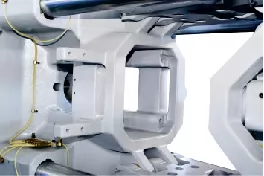

Direct-drive closing mold

Direct drive mechanism,quick response

for opening and closing mold.excellent

protection for low pressure.

|

High standard clamping unit

High standard clamping force

and parallelism adjustment are

achieved with stable clamping

state and reduced mold losses.

|

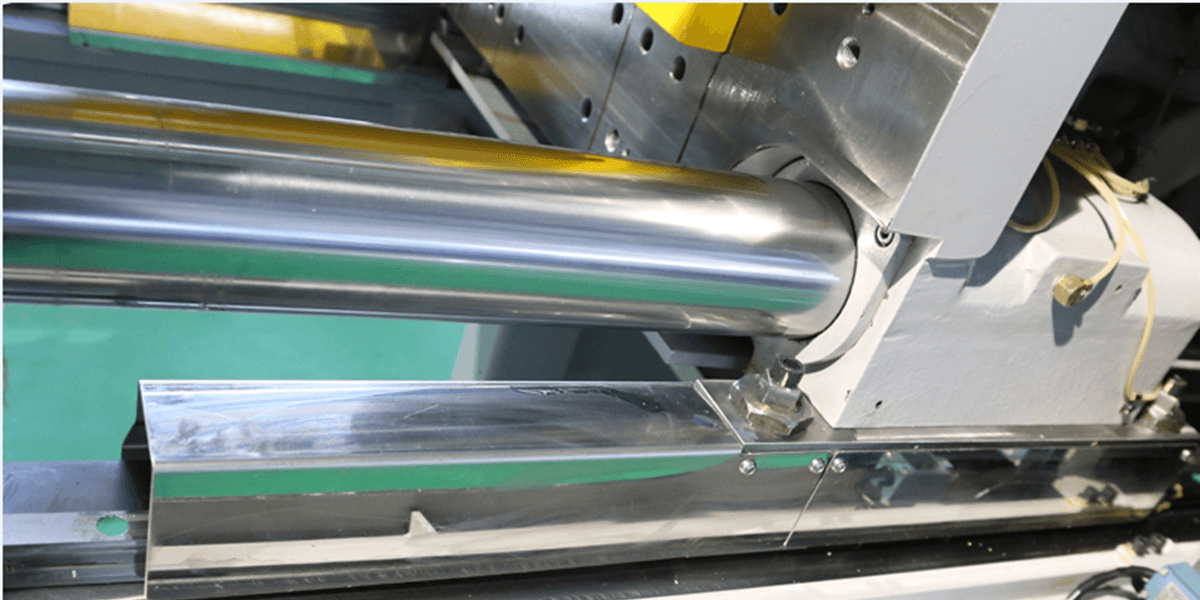

Support plate

High wear resistance and low

friction of the movable plate

supports sliding block, extends

mold service life.

|

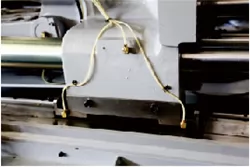

Full-automatic lubricating device

Reduce cost of maintenance。

|

|

|

|

|

|

Fixed plate structure

Optimized fixed plate structure.

reduces the tilting deforming of plate

|

Stress concentration moving plate

Optimized moving plate structure,

significantly improving the precision

of locking face.

|

Machinery safety bar

Reliable machinery safety bar.

|

Frame

High strength frame design and adopt

thick wall structure stesl components,

reducing the vibration of fast opening

and closing.

|

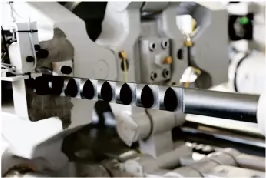

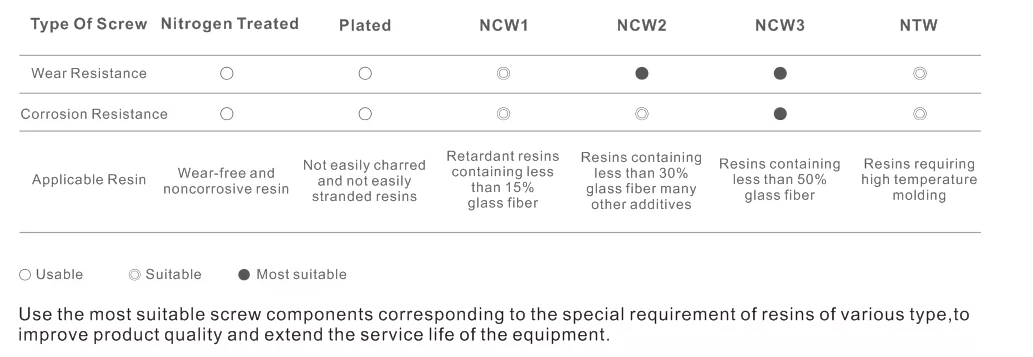

In Response To Diversified Plastics

With requirement of higher heat resistance for high-precision molded parts and the advent of plastics products that can substitute metal parts.the performance requirements of the molded products are increaing.Depending on the characteristics of the resins,from PO with long molding cycle to PC for optical lenses and ABS for structural parts.specially designed and developed screws by Anstrength based on factors such as resin heating temperature and injection speed may be used.together with specialized screw components with special material.special processing and special treatment.

Screw Options Of Various Types

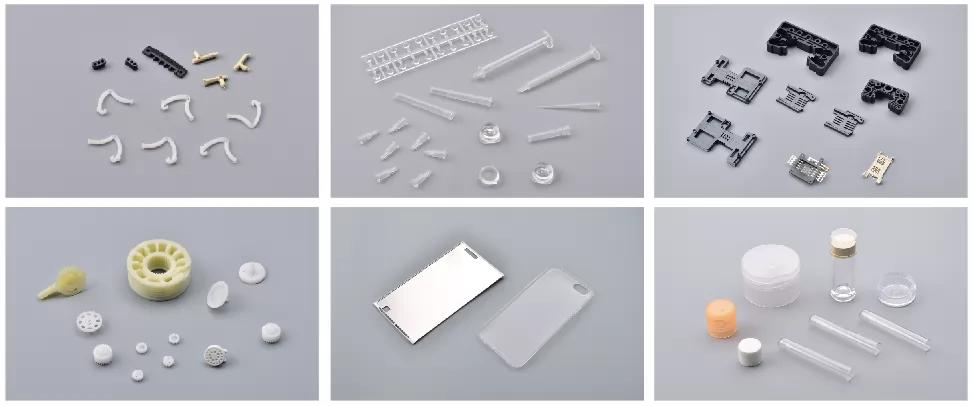

Diversified Products

Please tell us, what specifications of injection molding machine do you need?

Speak To One of Our Experts

Send Your Inquiry

*We respect your confidentiality and all information are protected.

People who viewed this item also viewed